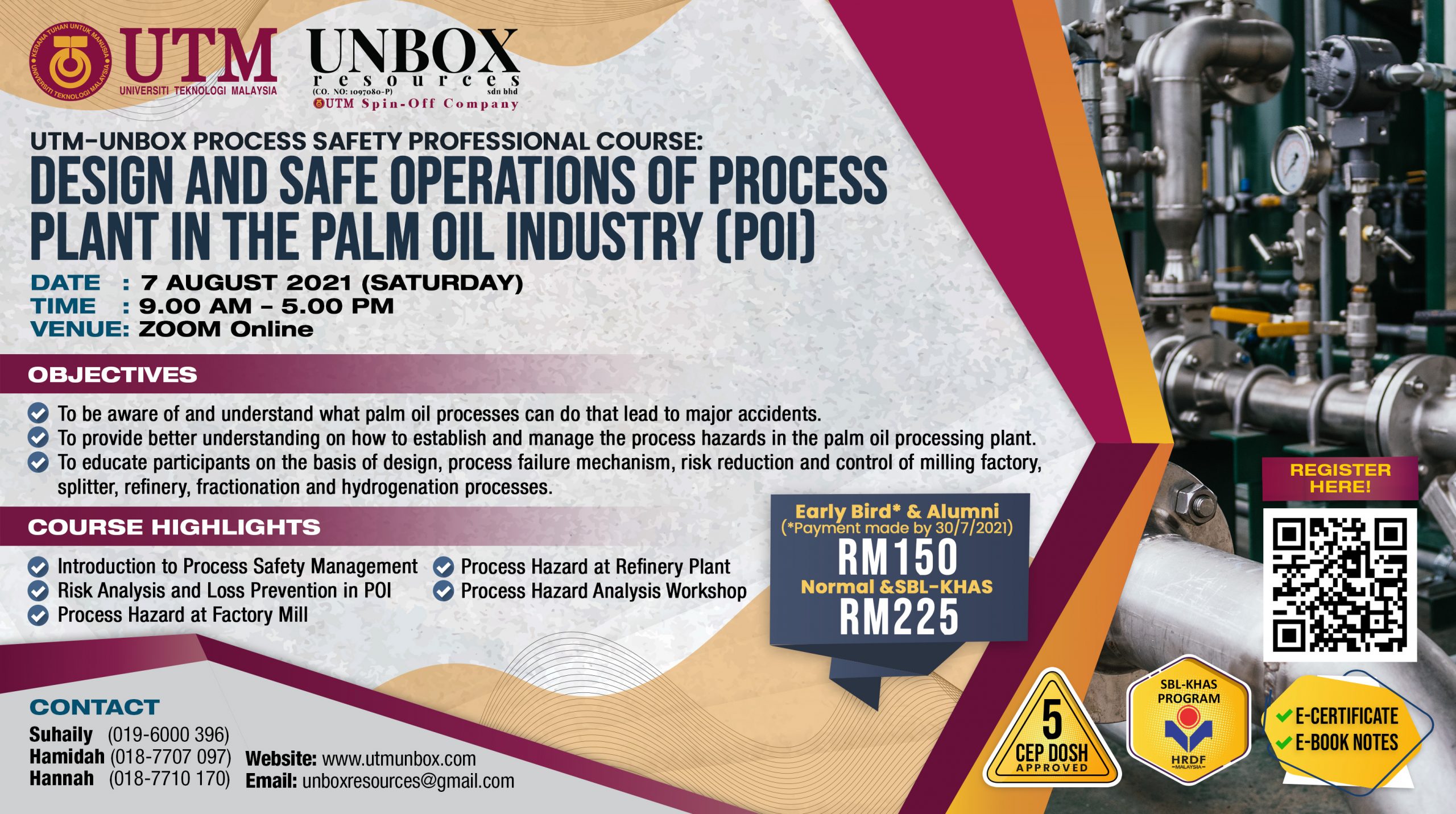

SEMINAR OBJECTIVES:

- To be aware of and understand what palm oil processes can do that lead to major accidents.

- To provide better understanding on how to establish and manage the process hazards in the palm oil processing plant.

- To educate participants on the basis of design, process failure mechanism, risk reduction and control of milling factory, splitter, refinery, fractionation and hydrogenation processes.

SEMINAR HIGHLIGHTS:

- Introduction to Process Safety Management

- Risk Analysis and Loss Prevention in POI

- Process Hazard at Factory Mill

- Process Hazard at Refinery Plant

- Process Hazard Analysis Workshop

DATE: 7 August 2021 (Saturday)

PLATFORM: Zoom Online

CEP: 5 POINTS

FEE:

RM 225 (SBL-KHAS CLAIM & NORMAL FEE)

RM 150 (ALUMNI & EARLY BIRD FEE)

What are you waiting for?

Let’s REGISTER NOW at this link

https://form.jotform.com/212021601880442

For further assistance,

Call/WhatsApp:

Ms Suhaili – 019-6000 396

Ms Hannah – 018-7710 170

Ms Hamidah – 018-7707 097

or email to:

unboxresources@gmail.com

PAYMENT DETAILS:

Beneficiary: UNBOX RESOURCES SDN BHD

Name of Bank: MAYBANK

Account Number: 551623213023

Payment Reference: Invoice No & Participant’s Name

Please send your payment proof to 019-6000 396 or account@utmunbox.com & unboxresources@gmail.com for our reference.

COURSE TOPICS & ITINERARY

TIME | DAY 1 |

08:30 – 09:00 | Registration |

09:00 – 10:30 | Session 1 – Introduction to Process Safety Management – Current issues and accident cases in POI – Legal requirements on Process Safety in Palm Oil Industry – 14/20 PSM Element |

10:30 – 10:45 | Ergonomic Break |

10:45 – 12:00 | Session 2 – Risk Analysis and Loss Prevention in POI – Risk Management Procedure – Inherently Safer Design, Passive Engineered & Active Engineered – Threat Line & Bow Tie Analysis |

12:00 – 13:00 | Group Activity – Process Hazard Analysis Workshop 1 |

13:00 – 14:00 | Lunch Break |

14:00 – 14:45 | Session 3 – Process Hazard at Factory Mill – Process hazard in Milling Factory – Basis of equipment design – boiler, sterilizer, process vessel etc. – Best practice and safe operation – boiler, sterilizer, process vessel etc. |

14:45 -16:15 | Session 4 – Process Hazard at Refinery Plant – Process hazard in Refinery Plant – Basis of equipment design – Splitter, Hydrogenation, Refinery, Fractionation etc. – Best practice and safe operation – Splitter, Hydrogenation, Refinery, Fractionation etc. |

16:15 – 17:00 | Group Activity – Process Hazard Analysis Workshop 2 |

17:00 – 17:30 | Wrap-up, Assessment and end of course |